gas assisted injection molding plastic parts

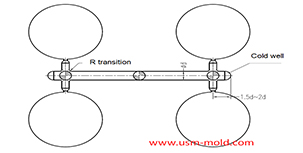

Key points of plastic injection mold runner systemThe sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...More+

Key points of plastic injection mold runner systemThe sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...More+

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

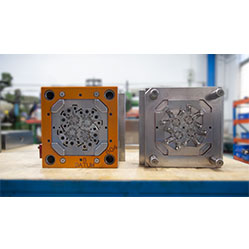

Insert Mold PartsInsert molding is injected with plastic part processing, the insert can be plastic or metal, normally it will be metal parts or thread parts, they must be in a fixed area before injection, so it will be fitting very well after injection finishing. Normally these products request a high standard of strength.More+

Insert Mold PartsInsert molding is injected with plastic part processing, the insert can be plastic or metal, normally it will be metal parts or thread parts, they must be in a fixed area before injection, so it will be fitting very well after injection finishing. Normally these products request a high standard of strength.More+

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Touch Switch Sensor MoldConvenience, comfort, artistry, and realize an environmentally friendly and energy-saving living environment.More+

Touch Switch Sensor MoldConvenience, comfort, artistry, and realize an environmentally friendly and energy-saving living environment.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

English

English русский

русский