gas assisted injection molding plastic parts

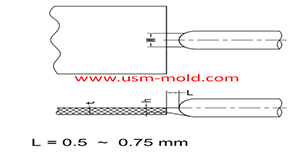

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

- Success factors of USMThe ability to produce mold at the high international standard, strong engineering and design capability, aggressive lead time and competitive priceMore+

Plastic Box MouldThe operation way of smart home appliances is very diversified, It can be operated with a smart touch screen, a scene remote control, a mobile phone, or a computer. There is no limitation for time and place which can be operated at any time and any place, any devices realize intelligent control.More+

Plastic Box MouldThe operation way of smart home appliances is very diversified, It can be operated with a smart touch screen, a scene remote control, a mobile phone, or a computer. There is no limitation for time and place which can be operated at any time and any place, any devices realize intelligent control.More+

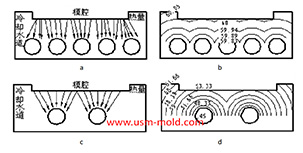

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

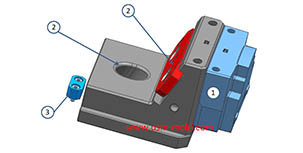

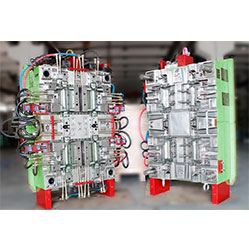

8 Cavity MoldAs a medical plastic injection mold supplier, It has its own unique solutions from medical product development to mold design, mold manufacturing, and injection molding production.More+

8 Cavity MoldAs a medical plastic injection mold supplier, It has its own unique solutions from medical product development to mold design, mold manufacturing, and injection molding production.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

English

English русский

русский