gas assisted injection mold

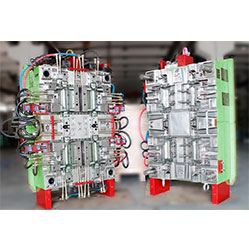

Unique Solutions Mold ProfileUSM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square meters.More+

Unique Solutions Mold ProfileUSM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square meters.More+

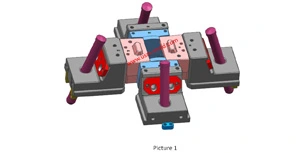

_20250317101516A021.jpg) The basic points of designing gas-assisted injection molding1. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel;2. The gas channel should be arranged in balan...More+

The basic points of designing gas-assisted injection molding1. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel;2. The gas channel should be arranged in balan...More+

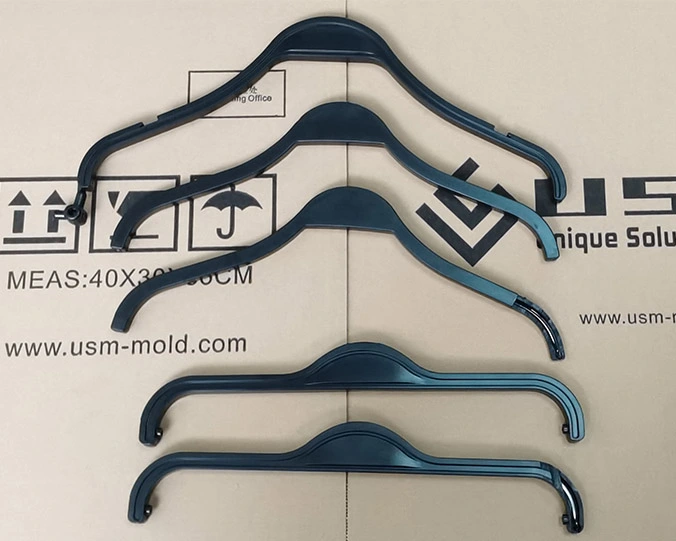

Gas-Assisted Injection Molding in Plastic HangersGas-assisted molding is a plastic injection molding technology that injects gas into the plastic in a molten state, forming a cavity inside the plastic, thereby achieving the purpose of reducing weigh...More+

Gas-Assisted Injection Molding in Plastic HangersGas-assisted molding is a plastic injection molding technology that injects gas into the plastic in a molten state, forming a cavity inside the plastic, thereby achieving the purpose of reducing weigh...More+

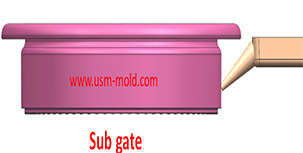

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

Amazing Outdoor TravelingOur team experienced wonderful outdoor walking a few weeks ago. we took a big bus from our office to the destination which is very natural and frosty with a very clean river dotted with cobblestones. we walked through the small rivers by naked feet.More+

Amazing Outdoor TravelingOur team experienced wonderful outdoor walking a few weeks ago. we took a big bus from our office to the destination which is very natural and frosty with a very clean river dotted with cobblestones. we walked through the small rivers by naked feet.More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

Medical TPE MoldSince the establishment of the factory, USM has provided injection molding products and injection mold services for many medical companies around the world, especially in medical multi-cavity and small products (pipetting tips) with rich and valuable experience.More+

Medical TPE MoldSince the establishment of the factory, USM has provided injection molding products and injection mold services for many medical companies around the world, especially in medical multi-cavity and small products (pipetting tips) with rich and valuable experience.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

English

English русский

русский