gas assisted injection mold in China

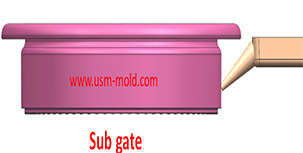

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

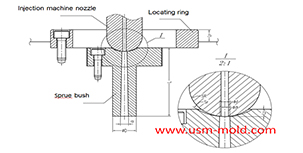

The main design points of the design of the plastic mold pouring systemThe main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision w...More+

The main design points of the design of the plastic mold pouring systemThe main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision w...More+

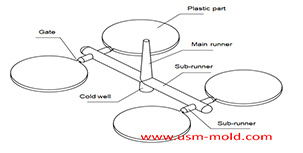

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

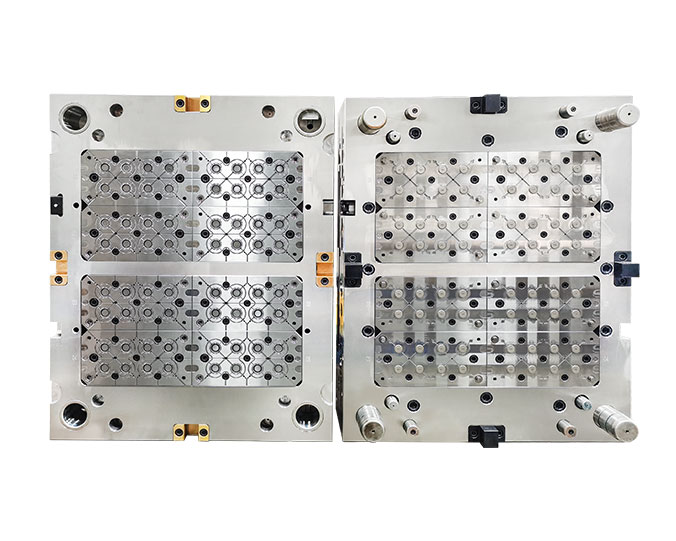

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

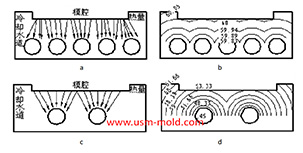

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

_20250317101412A020.jpg) Main application of gas-assisted molding technologyGas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the m...More+

Main application of gas-assisted molding technologyGas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the m...More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

- Success factors of USMThe ability to produce mold at the high international standard, strong engineering and design capability, aggressive lead time and competitive priceMore+

Video of CNC Machining Processing by Dongguan International Machine Tool Exhibition in 2021The 3rd China Machine Tool Purchasing Festival-DME Dongguan International Machine Tool Exhibition (hereinafter referred to as DME) was grandly closed at Guangdong Modern International Exhibition Center (Dongguan Houjie) on 13th Dec. 2021.More+

Video of CNC Machining Processing by Dongguan International Machine Tool Exhibition in 2021The 3rd China Machine Tool Purchasing Festival-DME Dongguan International Machine Tool Exhibition (hereinafter referred to as DME) was grandly closed at Guangdong Modern International Exhibition Center (Dongguan Houjie) on 13th Dec. 2021.More+

English

English русский

русский