gas assisted injection mold factory

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

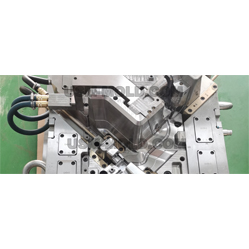

Automotive Water Intake Manifold MouldGas injection methods can be divided into two types, one is to inject gas together with the melt through the machine nozzle, and the other is to directly inject gas into the runner or cavity through the gas injection element (gas needle), the latter is divided into single-point intake and multi-point intake.More+

Automotive Water Intake Manifold MouldGas injection methods can be divided into two types, one is to inject gas together with the melt through the machine nozzle, and the other is to directly inject gas into the runner or cavity through the gas injection element (gas needle), the latter is divided into single-point intake and multi-point intake.More+

- Privacy PolicyThis Privacy Policy applies to the worldwide websites of which is part of the Sunkye International. It explains how we collect, process, share, secure and store personal information (information and ...More+

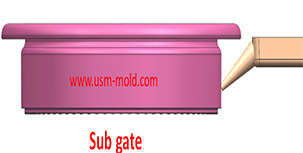

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

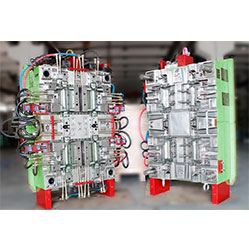

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

USM Blogo OpeningHello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.More+

USM Blogo OpeningHello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

Automotive Grille MoldThe part surface of the air intake grille generally has several treatment methods such as leather texture, sandblasting, paint spraying, and electroplating, the materials usually are PP, ABS, ASA, etc., and the surface of the bumper decorative grille is generally treated with leather texture and sandblasting, mainly PP material.More+

Automotive Grille MoldThe part surface of the air intake grille generally has several treatment methods such as leather texture, sandblasting, paint spraying, and electroplating, the materials usually are PP, ABS, ASA, etc., and the surface of the bumper decorative grille is generally treated with leather texture and sandblasting, mainly PP material.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

English

English русский

русский