gas assisted injection mold factory

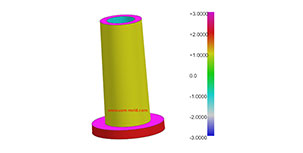

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

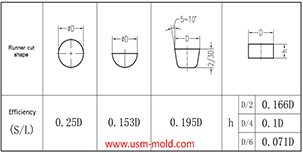

Hydraulic diameter conversion of runners in plastic mold gating system designHydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls, on...More+

Hydraulic diameter conversion of runners in plastic mold gating system designHydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls, on...More+

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

Side gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

Side gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

Pre-deformation MoldThe main reasons to cause the plastic parts are warpage and deformation1. The uneven wall thickness of each part of the plastic product deforms. Usually, the main part of the product is thicker and the ribs are thin, when the plastic parts are cooled.More+

Pre-deformation MoldThe main reasons to cause the plastic parts are warpage and deformation1. The uneven wall thickness of each part of the plastic product deforms. Usually, the main part of the product is thicker and the ribs are thin, when the plastic parts are cooled.More+

English

English русский

русский