Automotive handle

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

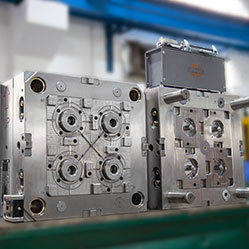

4 Cavity MoldA multi-cavity mold means that multiple identical parts are made in one set mold, and multiple identical parts can be produced in one injection cycle at the same time.More+

4 Cavity MoldA multi-cavity mold means that multiple identical parts are made in one set mold, and multiple identical parts can be produced in one injection cycle at the same time.More+

_20250317101516A021.jpg) The basic points of designing gas-assisted injection molding1. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel;2. The gas channel should be arranged in balan...More+

The basic points of designing gas-assisted injection molding1. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel;2. The gas channel should be arranged in balan...More+

Parallel barrel 2K injectionWhat is parallel barrel (2K) two-shot injection molding? What is 2K injection molding? Let’s see the what is called parallel barrel 2K injection molding. The injection molding machine used for...More+

Parallel barrel 2K injectionWhat is parallel barrel (2K) two-shot injection molding? What is 2K injection molding? Let’s see the what is called parallel barrel 2K injection molding. The injection molding machine used for...More+

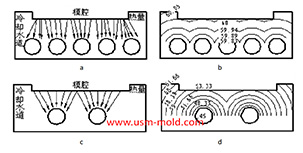

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

_20250317101606A022.jpg) Several common process of water-assisted injection molding introductionAccording to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...More+

Several common process of water-assisted injection molding introductionAccording to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...More+

Transparent PC Injection MoldType-J thermocouple, the positive electrode of this thermocouple is pure iron, and the negative electrode is constant (copper-nickel alloy).More+

Transparent PC Injection MoldType-J thermocouple, the positive electrode of this thermocouple is pure iron, and the negative electrode is constant (copper-nickel alloy).More+

English

English русский

русский