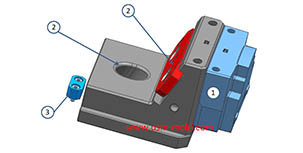

Slider angle designing tips

1. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched;

2. The angle of the locking surface must be bigger than the angle of the angle pin by 2° or more;

3. For the slider driven by the angle pin, the inclination angle of the slider shall not over 30°;

4. The angle (A) of the angle pin shall not over 22°.

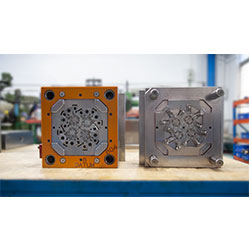

Popular USM Injection Molds

Related News about USM Injection Mold

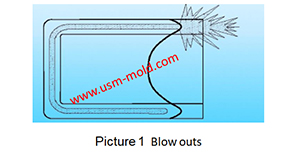

Gas-assisted injection molding product defects and solutions

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

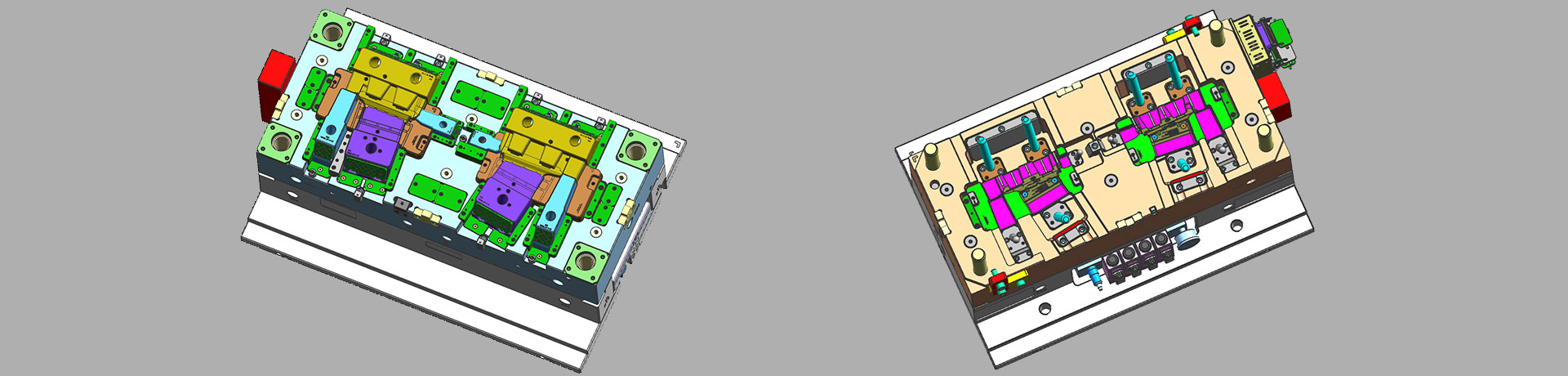

Slider designing tips 1

Aug 3, 20221. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...view

USM Blogo Opening

Oct 27, 2021Hello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need. USM is a professional plastic injection mold and molding...view

Slider spring hength and strength calculation

Apr 22, 2024Processing size: 1. ØD2=ØD+2 2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2) Spring length calculation: (refer to picture 1 for length calculation)...view

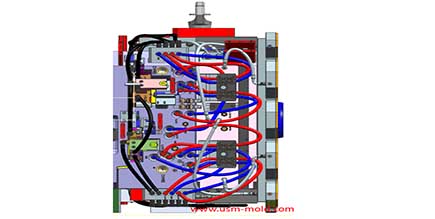

Plastic injection mold cooling system design notice

Feb 14, 2022Design notice of designing the cooling system: 1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer; 2....view

Insert pin of vengting design for molded parts

Mar 20, 2022Insert pin of venting: It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end...view

English

English русский

русский