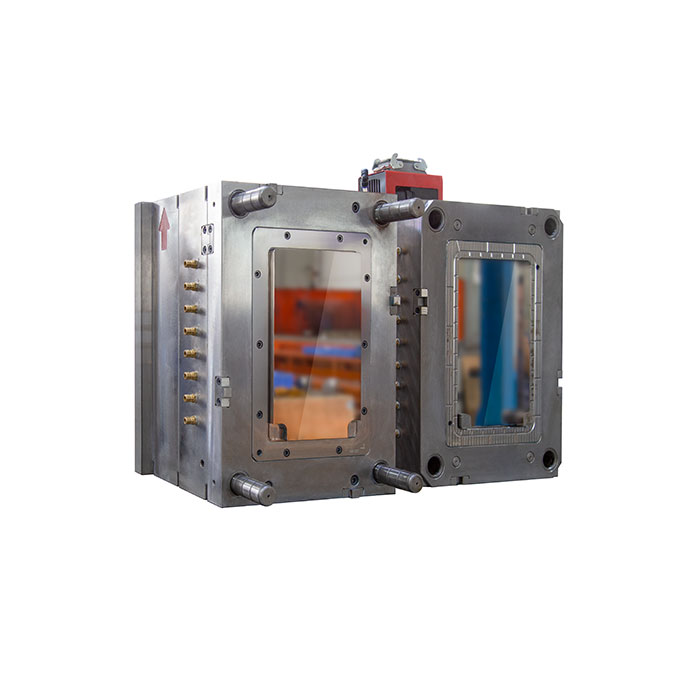

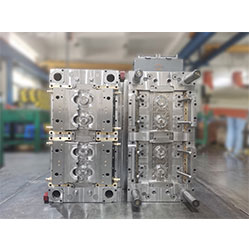

Multi Cavities Hot Runner Injection Mold

USM will offer suggestions according to product requirments, quantity, material cost and so on to chose the hot runner in order to help customers to save cost.

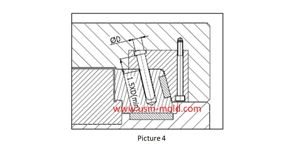

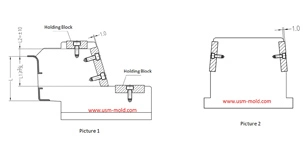

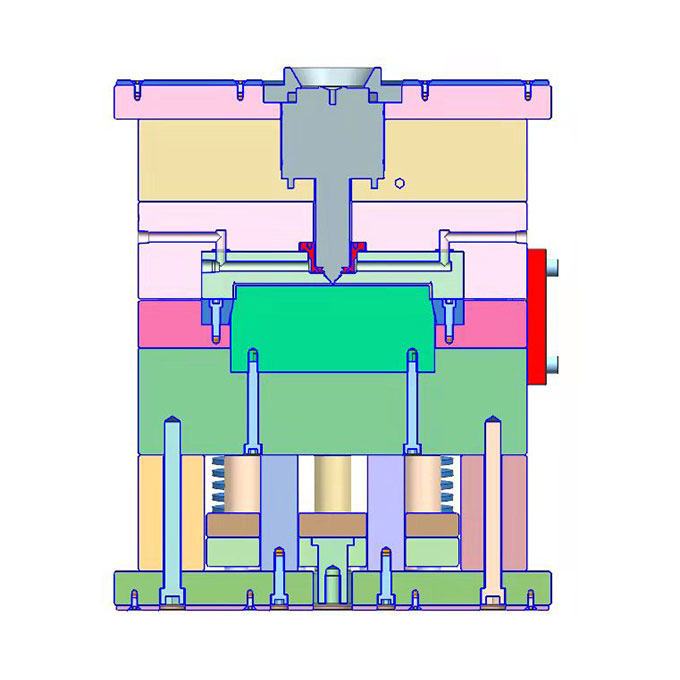

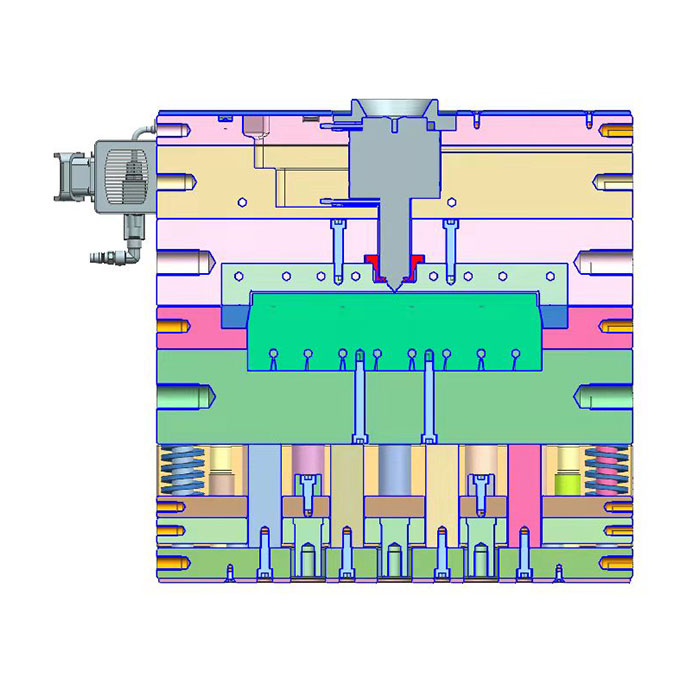

Hot runners are divided into open hot nozzles, pin-point hot nozzles, valve hot nozzles, etc. our engineer will chose the suitable hot runner according to product requirements and application.

USM has been working with many well-know hot runner suppliers very well, and we will ensure to satisfy customers requirements in lowest price and in the shortest time.

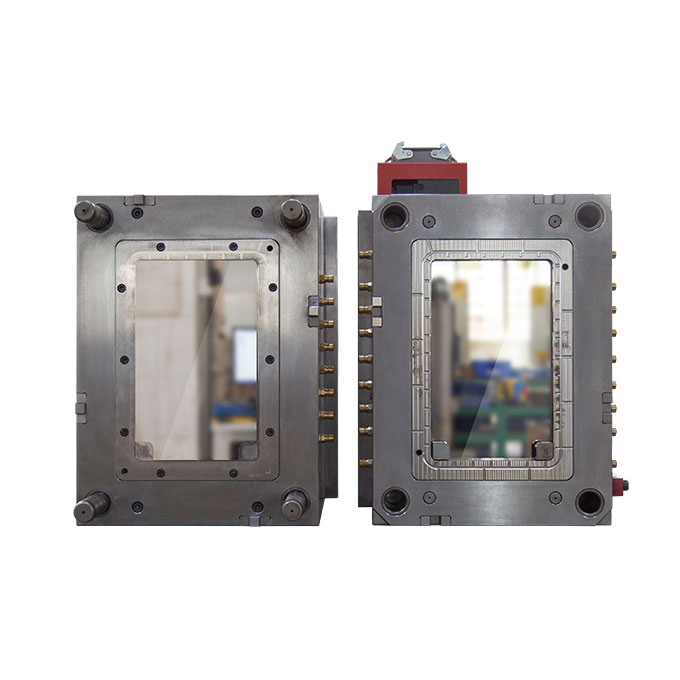

We made the hot runner molds are 16 pin-point hot runner system which has been delivered to customers for mass production successfully.

Multi Cavities Hot Runner Injection Mold Advantages

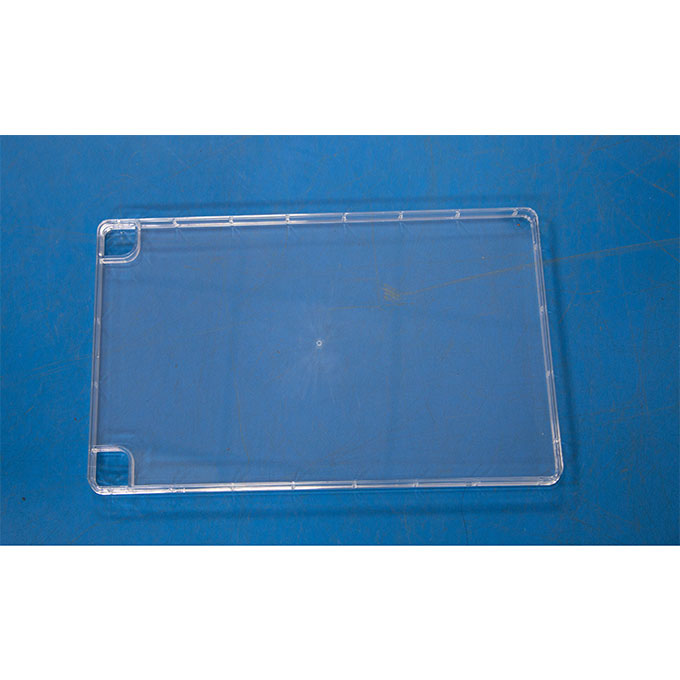

1. Shorten the injection cycle: because the hot runner does not have the limitation for the cooling time of the gating system, the product can be ejected directly after the product solid, so the injection cycle will be shorter than a cold runner. Many thin thickness parts can be injected within 5 seconds by a hot runner;

2. Saving plastic material: Since there is no cold runner in hot runner mold, there is no waste or very few runners during production, especially for expensive materials and large-volume projects, it can save cost a lot.

English

English русский

русский

_20250311083139A052.webp)