Gas-Assisted Injection Molding in Plastic Hangers

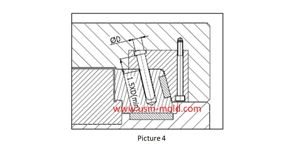

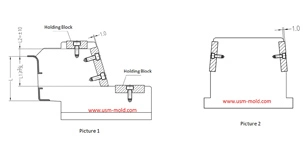

Gas-assisted molding is a plastic injection molding technology that injects gas into the plastic in a molten state, forming a cavity inside the plastic, thereby achieving the purpose of reducing weight, saving materials and reducing costs.

Advantages and Disadvantages of Plastic Hanger in Gas-Assisted Injection Molding

Advantages:

- High production efficiency: Using gas-assisted injection molding can improve production efficiency and reduce production time greatly.

- Saving material: Gas-assisted injection molding can save the plastic raw material and lower production costs.

- Stable product quality: Gas-assisted injection molding can improve the product quality which will make the part surface smoother and more stable shape.

- Environmental protection: It will not increase the large amount of waste during the gas-assisted injection molding process, and the impact on the environment is smaller than normal process.

Disadvantages:

- High investment: The price of gas-assisted injection molding equipment is high, and the initial investment cost is bigger than normal mold.

- High technical requirements: Gas-assisted injection molding technology requires high, professional operators are needed during operation.

- High maintenance: The maintenance cost of gas-assisted injection molding equipment is high, and it needs to be maintained and maintained regularly.

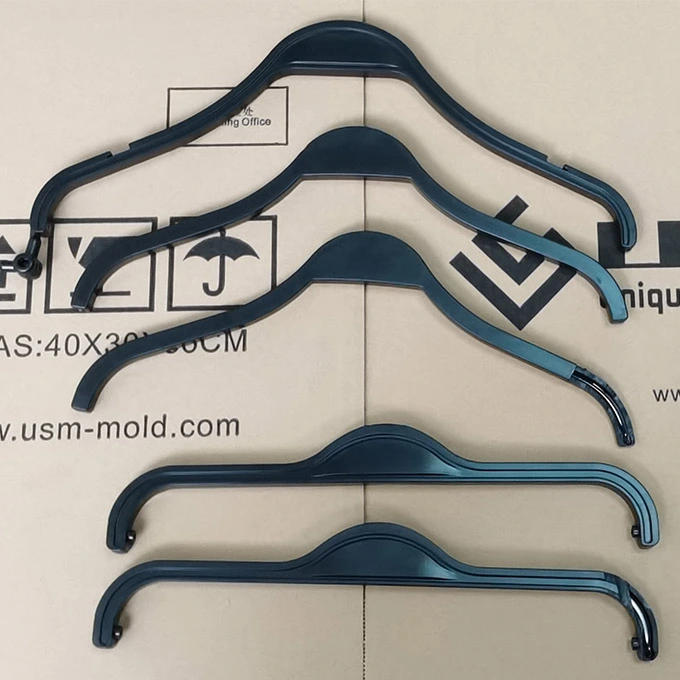

The Application of Gas-Assisted Injection Molding in Plastic Hangers

In the production of plastic hangers, the application of gas-assisted injection molding technology is more and more extensive.

- Material Saving: Gas-assisted injection molding technology can form a cavity inside the plastic hanger, which can reduce material using and reduce production cost greatly.

- Strength Improvement: Although gas-assisted injection molding technology forms a cavity inside the plastic hanger, but it will not reduce the strength. On the contrary, due to the existence of the cavity, the strength of the plastic hanger will be improved.

- Appearance Improvement: Gas-assisted injection molding technology can make the hanger surface smoother which will improve surface quality.

- Efficiency Improvement: Not only the gas-assisted injection molding technology can improve the production efficiency but also shorten the production cycle.

- Environmental Protection: Due to the use of gas-assisted injection molding technology, the waste generated in the production process will be greatly reduced, which is very beneficial to environmental protection.

Therefore, gas-assisted injection molding has a wide range of applications in the production of plastic hangers. It can not only improve production efficiency and reduce costs, but also improve the quality and environmental performance of the product.

Don't Hesitate to Contact Us Now.

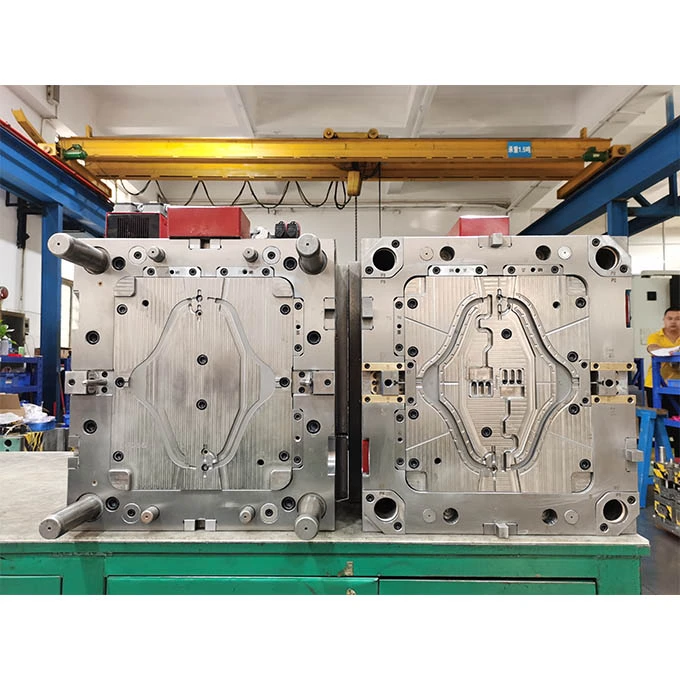

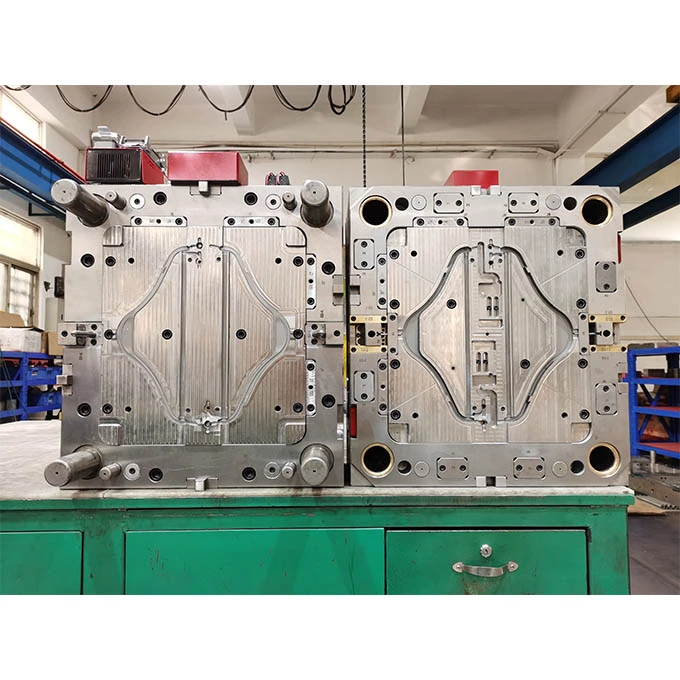

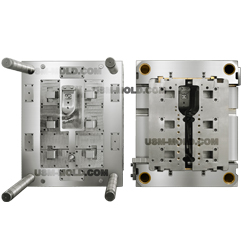

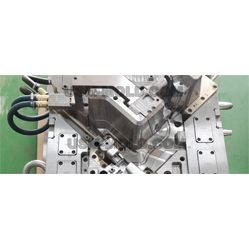

Related Gas & Water Assisted Injection Mold

English

English русский

русский