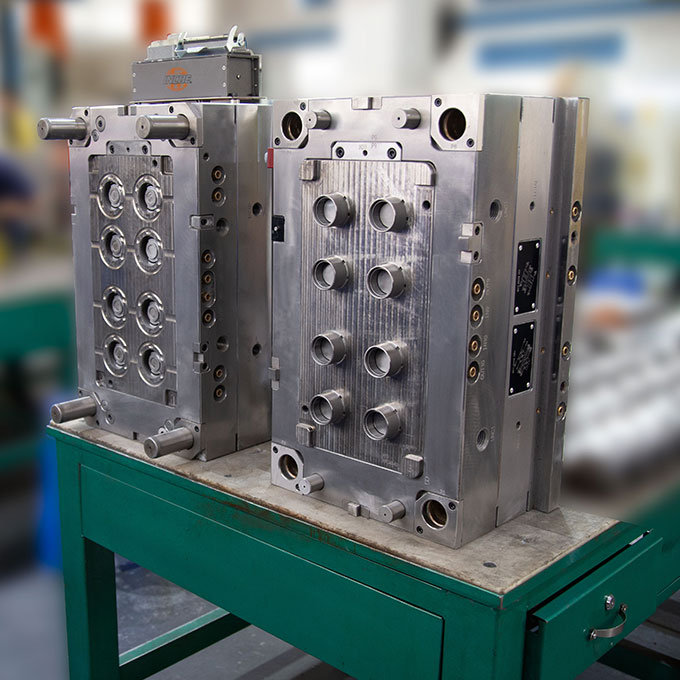

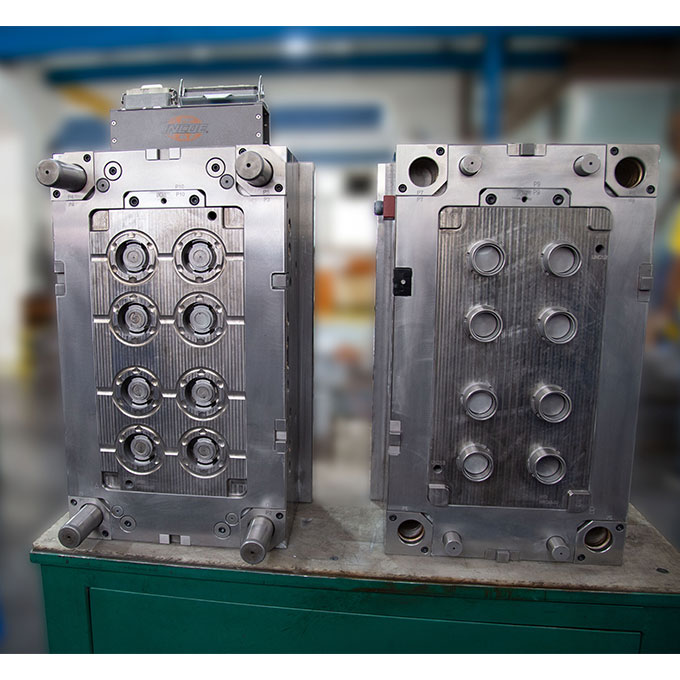

Cold Runner Mould

Home appliances injection mold advantages:

1. The mold without a heating system, the mold cost is cheaper than a hot runner;

2. The mold production cycle is quicker than hot runner mold, there is unnecessary to make special hot runner system installation holes which can save processing time;

3. Mold maintenance is simple;

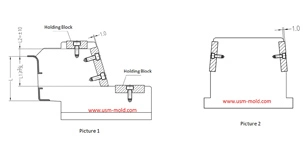

4. The mold thickness is thinner which is unnecessary to install the hot runner system, the cold runner mold will be 100-200mm shorter than the hot runner mold, and it can be produced with a smaller machine.

Hot Runner Mold Types

The hot runner is divided into two types: single hot nozzle and hot runner with manifold, and the hot nozzle can be divided into:

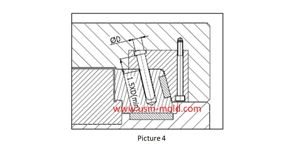

1. Direct gate of hot runner: the advantage is that the pressure loss is small, the structure is simple, but the disadvantage is that it is easy to gate drooling and string, the appearance of the part surface is not good, etc;

2. Pin-point gate of hot runner: The advantage is that the part surface is good, not easy to drooling and string, and prevents flow mark on the part surface, the disadvantage is that the pressure loss is too much and difficult to change color;

3. Valve gate of hot runner: the advantages of small pressure loss, good part surface, not easy to gate drooling and string, timing control, and adjustable welding line, etc., the disadvantage is that the structure is complex, the mold thickness is thicker than the general hot runner, and the cost is high.

English

English русский

русский

_20250311083139A052.webp)