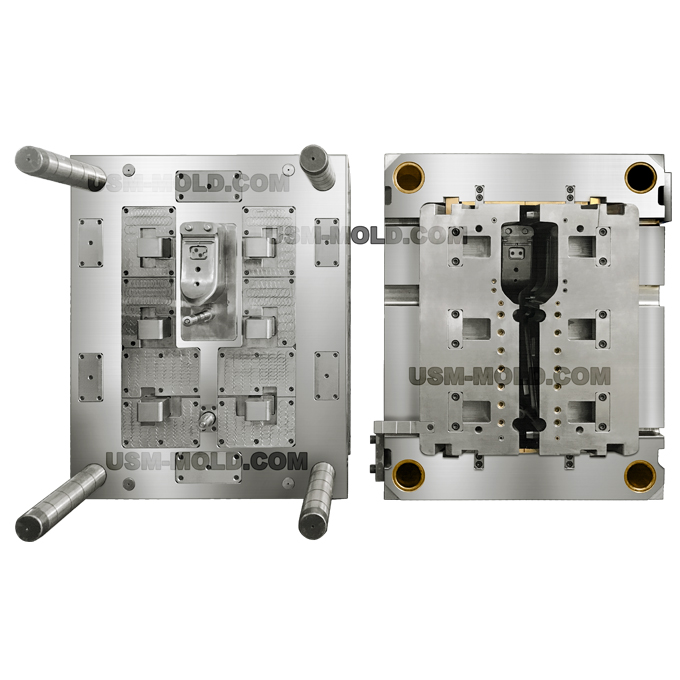

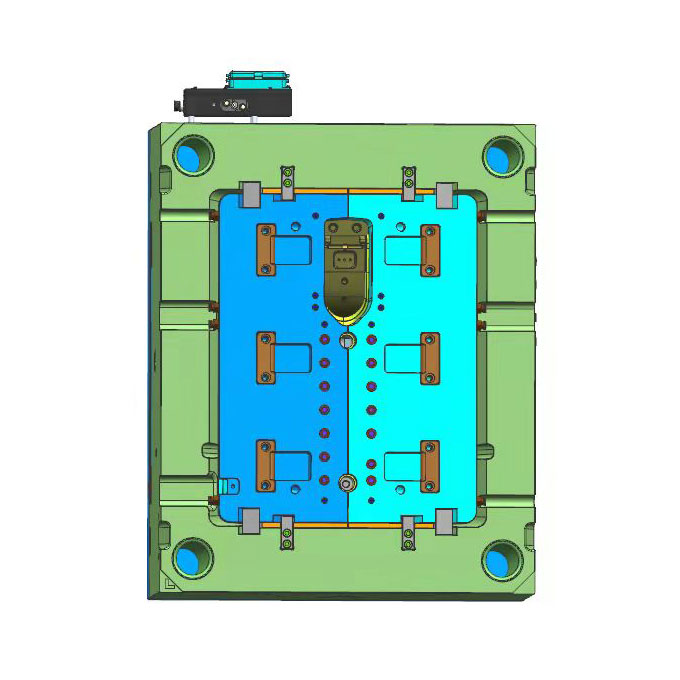

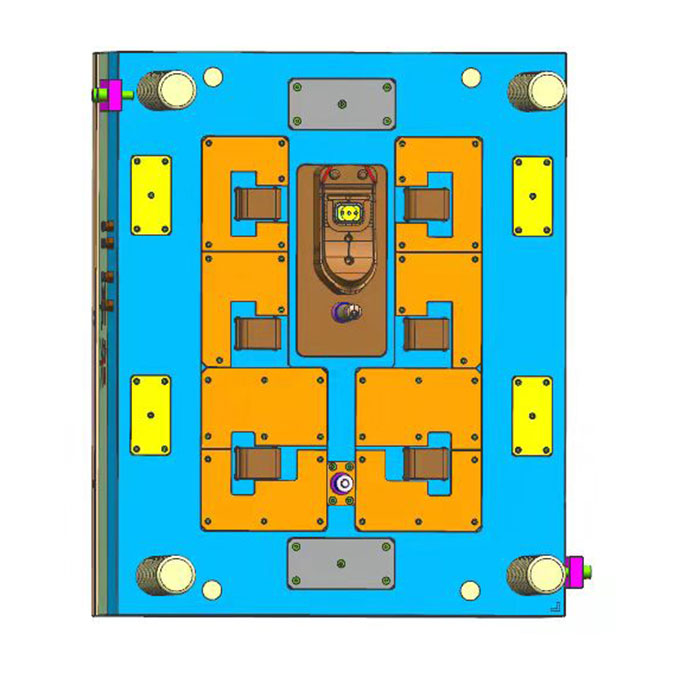

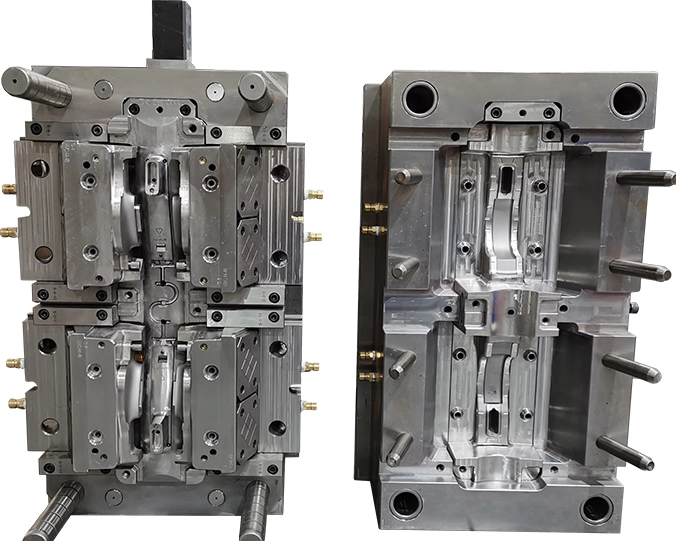

Bike Frame Mold for Kids

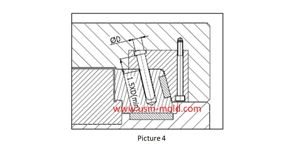

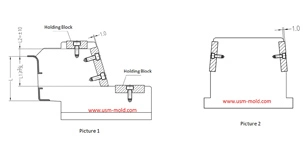

Nowadays, gas-assisted injection molding has been successfully applied to the fields of the automotive, home appliance, furniture, daily necessities, office supplies, and other fields, the main products are automotive doors, bumpers, window guides, door handles, large-screen TV shells, and integral tables, chairs, etc., enable many plastic parts that cannot be molded by normal injection molding methods or are difficult to be molded, opening up a new way for plastic parts molding.

Advantages of Child Balance Frame Mold

1. Saving raw material up to 50%;

2. Reducing product weight;

3. Shorten the injection cycle;

4. Short shot can reduce injection pressure and clamping force.

Don't Hesitate to Contact Us Now.

Related Gas & Water Assisted Injection Mold

English

English русский

русский