Automotive AC Air Outlet

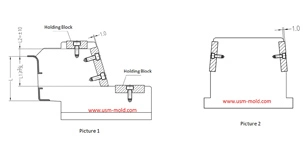

The air outlet panel of automotive AC is a critical product, the mold design should focus on the factors to the surface quality, for example, the ribs position needs to consider the rib raio to the wall thickness, and whether there is a leather texture spray painting or electroplating. The gate should consider whether it will affect the product welding line, the assembly relationship with other parts, and so on.

Automotive AC fans are both critical and functional parts, normally, the material with glass fiber is mainly reflected in the floating fiber and flow marks on the part surface when injection, these two points should be dealt with by injection gate design and injection parameter, another is because the fans are also the critical part which is particularly strict to parting. it mainly depends on whether the precise positioning of mold design at the beginning and the later stage depends on the manufacturing equipment accuracy and the rationality of the manufacturing technology.

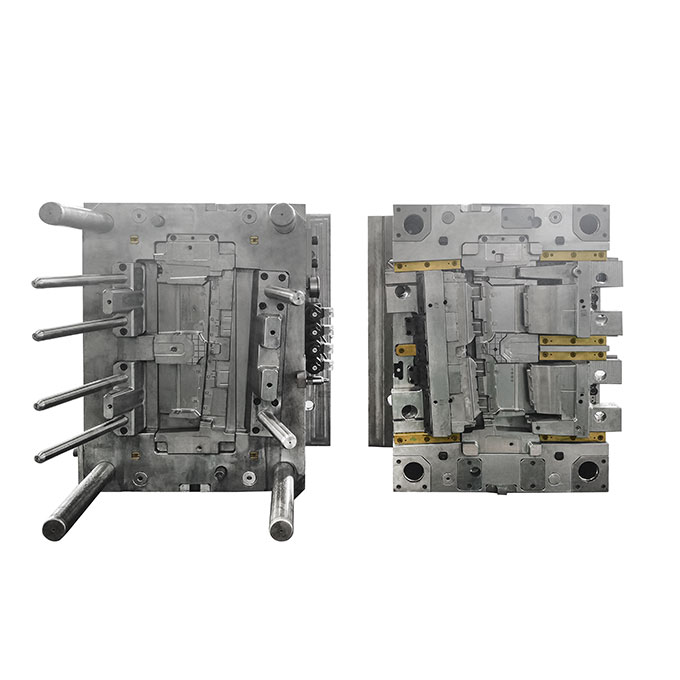

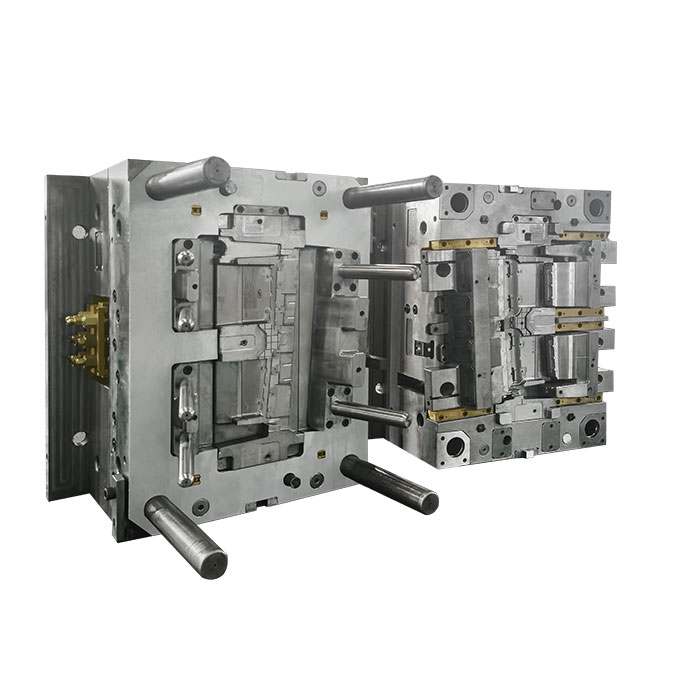

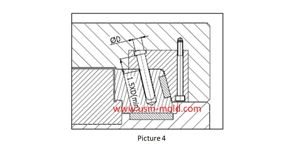

Automotive Outlet Shell Of AC

The automotive outlet shell of AC is the functional carrier of the automotive outlet shell of AC, It belongs to the category of functional parts in the field of outlet molds and which is also a very key part, the material is generally made by PP. The mold structure is complex and the design is relatively difficult, all the automotive outlet parts are basically installed on this product, this type of mold design should be considered the mold structure, runner system, cooling system, and mold fixing accuracy, etc.

English

English русский

русский