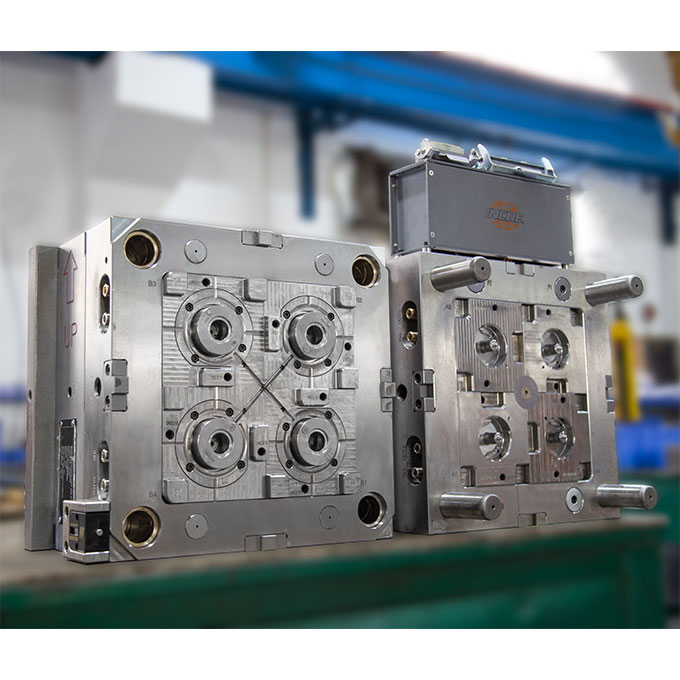

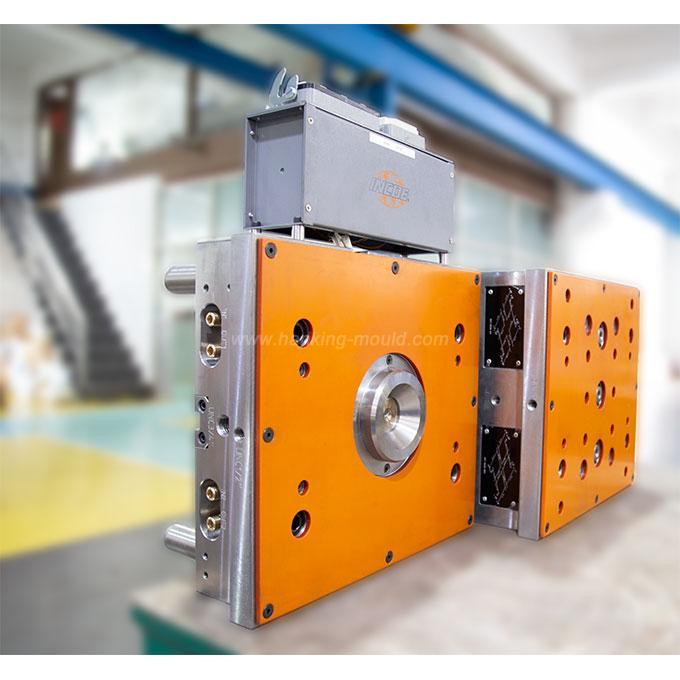

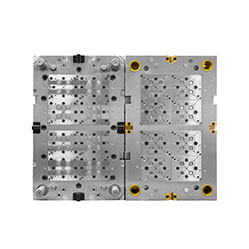

4 Cavity Mold

The multi-cavity mold can save production time, for example, one mold can produce 1 piece of part in one minute, but it can be produced 32 pieces of parts in one minute if we make a 32-cavity mold. Multi cavity mold requires very high machining accuracy. If the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.

Advantages of 4 Cavities Plastic Injection Mold

1. Saving production cost: the injection cost can be saved a lot when producing multiple products at the same time. For example, a 64-multi cavity mold can produce 64 pieces of parts in one minute, but if we use one 32-cavity mold which needs to get 64 pieces of parts, then it means it will need to make 2 times, so the production cost will be increased;

2. Saving mold cost: to make 2 sets 32-cavity mold cost is about 1/3 higher than one set 64-cavity mold;

3. Order target achievement rate: it will be difficult for a single cavity mold to produce 1 million parts in a short time, but a multi-cavity mold is easy to deliver on time.

English

English русский

русский