Plastic injection mold runner system design points

When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically considered to minimize the proportion of waste generated by the runner; finally, it should be easy to repair the gate mark on the plastic part.

The main points of gating system design are as follows:

1. The gate positio should ensure that when the plastic flows into the cavity, it faces the wide part of the cavity, that is, the melt should flow from the thick-walled part of the cavity into the thin-walled part. If the melt flows from the thin-walled part to the thick-walled part, the speed will drop quickly and the temperature will drop rapidly which is not conducive to filling;

2. In order to prevent the plastic rushing to the cavity, core or insert directly, it is necessary to ensure that the plastic melt can flow to all parts of the cavity as soon as possible and to avoid deformation of the core or insert;

3. Try to avoid making plastic parts cause weld marks, and make the weld marks occur in unimportant parts;

4. The gate position and its plastic inflow direction can flow in evenly along the parallel direction of the cavity when the plastic flows into the cavity, and it is conducive to the discharge of gas in the cavity;

5. If fully automatic operation is used during production, it must be ensured that the condensate of the gating system can be smoothly and automatically demolding together with the plastic parts;

6. There should be a good venting structure and sufficient cold well in the gating system, the air and cold material in the gating system should be brought into the cavity as less as possible, which will affect the parts quality;

7. When a mold has multiple cavities, it is necessary to prevent the plastic parts with very different sizes from being placed in the same mold, if the part size differs by more than 4 times, it is difficult to make filling balanced;

8. If the projected area of the plastic part is big, we should avoid opening a gate on one side of the mold when designing the gating system, otherwise it will cause uneven force during injection molding;

9. The design of gating system should consider shortening the production cycle and increasing productivity.

Five Major Steps of the Injection Mold Production Process

Dec 9, 2021Injection mold manufacturing can be roughly divided into the following steps: Process analysis of plastic products. Before the mold design, the designer should fully analyze and study whether the...view

Water assisted injection molding introduction

May 11, 2022Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic...view

Venting of parting surface

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

Unique Solutions Mold Profile

Dec 27, 2021USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square...view

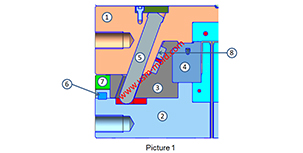

The common fixing method of angle pin

May 10, 2024The angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...view

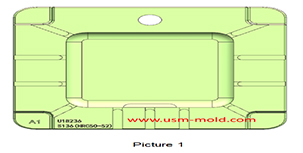

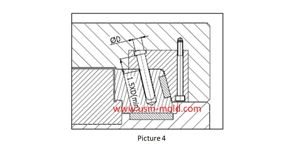

Slider of side core pulling mechanisum assembling

Jul 21, 2022The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...view

English

English русский

русский