Limitations of gas-assisted injection molding technology

Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following aspects:

.png)

1. Comparing with traditional injection molding, the injection parameters of gas-assisted injection molding are doubled, and the sensitivity of parts to process parameters is improved, therefore, in the molding process, the precise control of various process parameters has a slight error, then the part quality and the stability of the production process will be affected.

2. When the gas channel structure design and mold design of the gas injection mold part are unreasonable, or the operation of the gas-assisted equipment is incorrect, it will cause issues such as poor gas channel and blockage of the needle and so on, it will lead to unstable production or lower productivity.

.png)

3. Gas-assisted injection molding requires a special gas-assisted equipment and molds, use purified nitrogen, or modify the nozzle of the injection machine, or open a gas channell in the mold and add a gas needle to guide the gas into the mold cavity and core, sometimes in the mold pressure and temperature sensors are placed in the cavity to improve control accuracy, so the initial investment cost is relatively high.

4. Higher quality requirements for operators and engineers, traditional injection molding experience cannot solve the process defects of gas-assisted parts, engineers must use CAE software to perform simulation analysis before designing in order to determine a reasonable design plan and various process parameters to reduce repeated mold trial and modification cost.

The design principle of the exhaust slot

Mar 6, 2022The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product...view

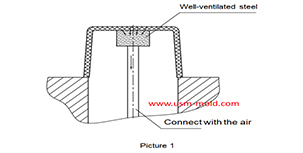

Well-ventilated steel of venting design for molded parts

Mar 14, 2022Well-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow the...view

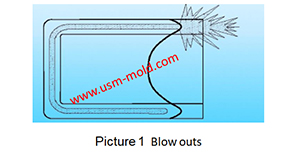

Gas-assisted injection molding product defects and solutions

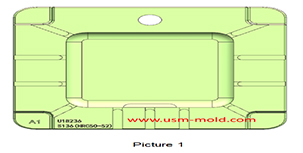

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

Venting of parting surface

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

What is the side parting and core pulling mechanisms with their function?

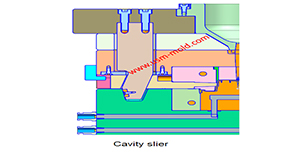

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

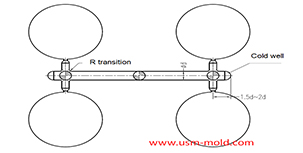

Key points of plastic injection mold runner system

Jan 12, 2022The sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...view

English

English русский

русский