Gas-assisted Injection Molding Equipment

The gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection molding machine is the injection signal connection line. After the injection molding machine transmits an injection signal injection start or screw position to the gas-assisted control unit, it starts a gas injection process, and when the next injection process starts, another injection signal is given, and another cycle starts and so on. The gas used in gas-assisted injection molding must be an inert gas (usually nitrogen), the maximum pressure of the gas is 35MPa, and the maximum pressure of the gas can be up to 70MPa, and the nitrogen purity is ≥98%. The gas-assisted control part is a device that controls the gas injection time and pressure, it has a multi-group gas circuit design that can control the gas-assisted production of multiple injection molding machines at the same time, the gas-assisted control part has a gas recovery function to reduce gas as much as possible consumption.

Gas-assisted Injection Molding Equipment

Apr 10, 2022The gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection...view

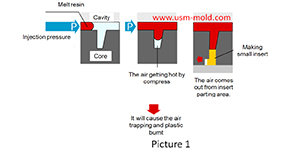

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

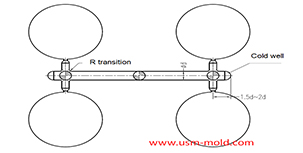

Key points of plastic injection mold runner system

Jan 12, 2022The sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...view

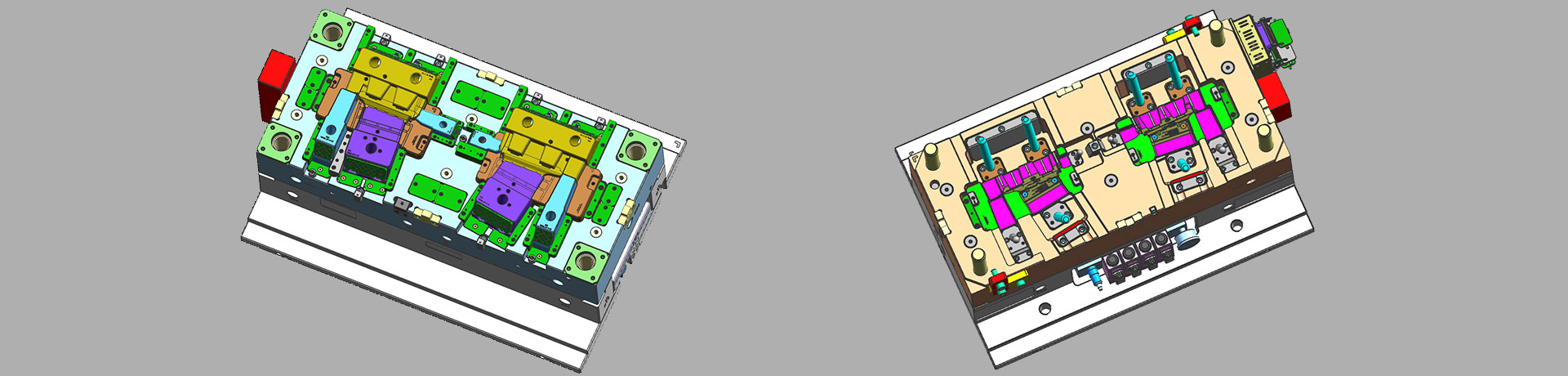

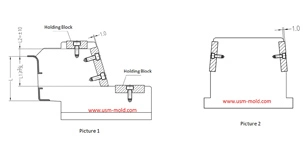

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

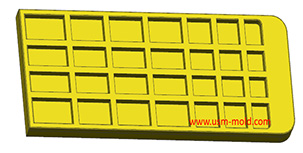

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

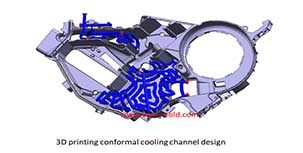

Controling method of plastic injection mold temperature

Feb 15, 2022Except for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat...view

English

English русский

русский