gas assisted injection molding factory

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

PLC Controller Shell MoldMore and more people will have a high standard for a better life, most of home appliance product surfaces were made by mirror polishing, it requires for high standard to mold steel and polishing way, good mold steel without a technical polishing engineer, the product can not reach the high standard, they always work together.More+

PLC Controller Shell MoldMore and more people will have a high standard for a better life, most of home appliance product surfaces were made by mirror polishing, it requires for high standard to mold steel and polishing way, good mold steel without a technical polishing engineer, the product can not reach the high standard, they always work together.More+

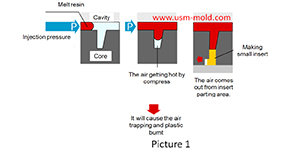

Vacuum venting mold design for plastic molded partsThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

Vacuum venting mold design for plastic molded partsThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

New Five-axis CNC Machine ArrivalThe new 5 axis CNC machining machine has arrived in our workshop on 6th Nov. 2021 and is now putting into use.GMU-6350 type CNC machining machineWorking stroke (XYZ): 630*500*550Maximum loading: 800kg...More+

New Five-axis CNC Machine ArrivalThe new 5 axis CNC machining machine has arrived in our workshop on 6th Nov. 2021 and is now putting into use.GMU-6350 type CNC machining machineWorking stroke (XYZ): 630*500*550Maximum loading: 800kg...More+

The main reasons for air trapping of plastic injecton moldDuring the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized.The mechanism of air trapped...More+

The main reasons for air trapping of plastic injecton moldDuring the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized.The mechanism of air trapped...More+

_20250317101412A020.jpg) Main application of gas-assisted molding technologyGas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the m...More+

Main application of gas-assisted molding technologyGas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the m...More+

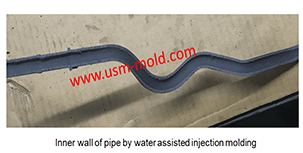

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

English

English русский

русский