gas assisted injection mold factory

Plastic injection mold runner system designThe gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate dir...More+

Plastic injection mold runner system designThe gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate dir...More+

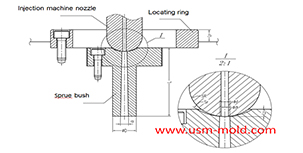

The main design points of the design of the plastic mold pouring systemThe main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision w...More+

The main design points of the design of the plastic mold pouring systemThe main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision w...More+

Plastic Household MouldAdvantages of Smart Home Appliance MoldMeet different demandsIn order to meet the different types of demands, grades, and styles, the control host of the smart home system can also be upgraded online.More+

Plastic Household MouldAdvantages of Smart Home Appliance MoldMeet different demandsIn order to meet the different types of demands, grades, and styles, the control host of the smart home system can also be upgraded online.More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

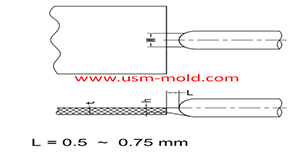

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

Water Proof Plastic Enclosure MoldThe product will be made by two times, which will inject the second piece after finishing the first piece in the other mold and different injection machine, normally will be no specific request for 2 different pieces injection time, injection machine.More+

Water Proof Plastic Enclosure MoldThe product will be made by two times, which will inject the second piece after finishing the first piece in the other mold and different injection machine, normally will be no specific request for 2 different pieces injection time, injection machine.More+

English

English русский

русский