Child balance bike shell

Automotive Water Intake Manifold MouldGas injection methods can be divided into two types, one is to inject gas together with the melt through the machine nozzle, and the other is to directly inject gas into the runner or cavity through the gas injection element (gas needle), the latter is divided into single-point intake and multi-point intake.More+

Automotive Water Intake Manifold MouldGas injection methods can be divided into two types, one is to inject gas together with the melt through the machine nozzle, and the other is to directly inject gas into the runner or cavity through the gas injection element (gas needle), the latter is divided into single-point intake and multi-point intake.More+

- Find UsCustom injection mold manufacturing and plastic injection molding in China.Address: No.136 Xingwu Road,Wusha Community, Changan Town,Dongguan, ChinaTel: 86-0769-8539 0209Email: [email protected]...More+

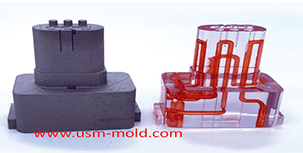

Conformal cooing channel of plastic injection moldThe conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product wel...More+

Conformal cooing channel of plastic injection moldThe conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product wel...More+

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

Different treatment of plastic injection mold cooling system principlesDifferent treatment principle:1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be he...More+

Different treatment of plastic injection mold cooling system principlesDifferent treatment principle:1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be he...More+

Parallel barrel 2K injectionWhat is parallel barrel (2K) two-shot injection molding? What is 2K injection molding? Let’s see the what is called parallel barrel 2K injection molding. The injection molding machine used for...More+

Parallel barrel 2K injectionWhat is parallel barrel (2K) two-shot injection molding? What is 2K injection molding? Let’s see the what is called parallel barrel 2K injection molding. The injection molding machine used for...More+

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Injection MoldingUSM is a professional one-stop service for plastic injection molding companies in China, with our rich experience by mold-making capabilities, we ensure that mass products can be manufactured in the shortest time.More+

Injection MoldingUSM is a professional one-stop service for plastic injection molding companies in China, with our rich experience by mold-making capabilities, we ensure that mass products can be manufactured in the shortest time.More+

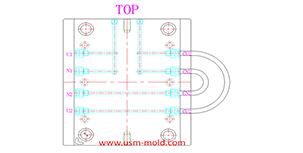

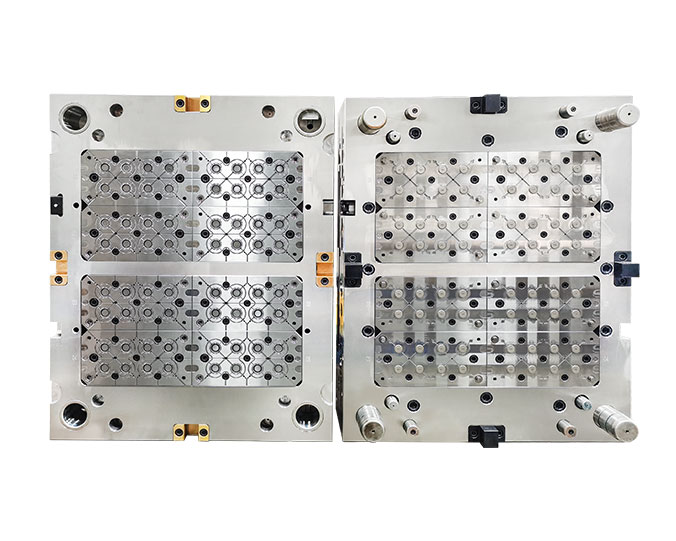

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

English

English русский

русский