Automotive handle mold supplier

Air Chamber MoldWith over 15 years of pre-deformed mold, USM Mold has mastered scientific and complete pre-deformation mold technology, from project management, mold flow analysis, design, manufacturing, assembling, mold trial, and final measurement.More+

Air Chamber MoldWith over 15 years of pre-deformed mold, USM Mold has mastered scientific and complete pre-deformation mold technology, from project management, mold flow analysis, design, manufacturing, assembling, mold trial, and final measurement.More+

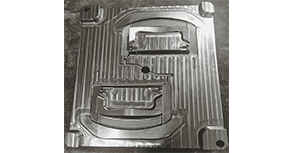

Plastic Switch MouldUSM is an ISO9001:2015 certified mold and injection molding factory. It has its own unique solutions from smart home appliance product development for mold design, mold manufacturing, and injection molding production.More+

Plastic Switch MouldUSM is an ISO9001:2015 certified mold and injection molding factory. It has its own unique solutions from smart home appliance product development for mold design, mold manufacturing, and injection molding production.More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

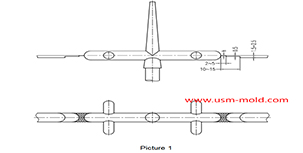

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

Limitations of gas-assisted injection molding technologyGas-assisted injection molding technology has obvious advantages in thick wall thicknes and tpipe parts, but this technology still has many limitations, which are mainly reflected in the following asp...More+

Limitations of gas-assisted injection molding technologyGas-assisted injection molding technology has obvious advantages in thick wall thicknes and tpipe parts, but this technology still has many limitations, which are mainly reflected in the following asp...More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

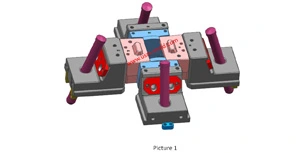

What is 2K molding? What is L-shaped barrel two-color injection molding? What is 90-degree vertical barrel two-color injection molding?More+

What is 2K molding? What is L-shaped barrel two-color injection molding? What is 90-degree vertical barrel two-color injection molding?More+

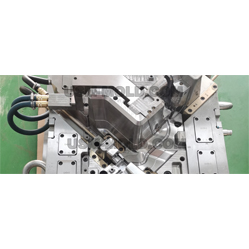

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

English

English русский

русский