Automotive ceiling handle mold

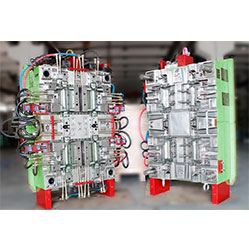

Mold AssemblingTo assemble the mold but not without fitting is the goal for every bench worker, and it has become the soul of every USM employee.More+

Mold AssemblingTo assemble the mold but not without fitting is the goal for every bench worker, and it has become the soul of every USM employee.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

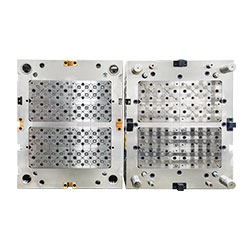

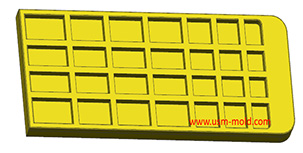

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

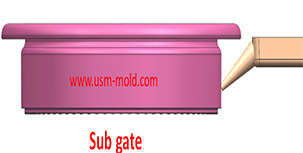

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

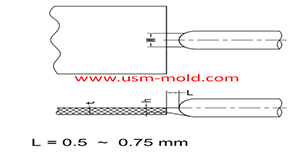

Plastic part ribs desiginingThe ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of t...More+

Plastic part ribs desiginingThe ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of t...More+

Overmolding & 2k MoldingMaterial selection for two-color products: The same type of material of different colors is usually used for two-color injection molding so that the bonding strength of the first color and the second color plastic is the best.More+

Overmolding & 2k MoldingMaterial selection for two-color products: The same type of material of different colors is usually used for two-color injection molding so that the bonding strength of the first color and the second color plastic is the best.More+

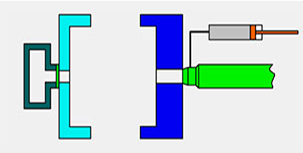

The difference between full shot and short shot of gas-assisted injection moldingGas-assisted injection molding can be divided into short shot and full shot.Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filli...More+

The difference between full shot and short shot of gas-assisted injection moldingGas-assisted injection molding can be divided into short shot and full shot.Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filli...More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

English

English русский

русский