Slider designing tips 1

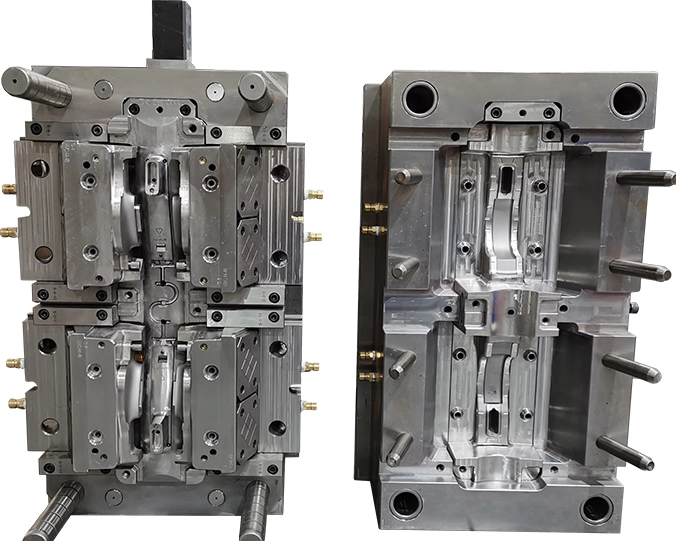

1. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengthened;

2. In principle, the length of the sliding part of the slider should be bigger than 1.5 times the height of the slider;

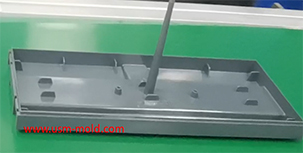

3. The mating surface of the cross-section surface of the slider going deep into the fixed die is made into a side slope of 3~5° to avoid air or unilateral, as shown in 1 in picture 1;

4. The maximum angle of the angle pin shall not exceed 22°,, and the wedge angle of the slider is 2-3° larger than that of the angle pin;

5. The entrance of the angle pin hole of the slider should be made into an R angle, as shown in 2 in picture 1;

6. The matching gap between the angle pin hole of the slider and the angle pin should be avoided by 0.5-1.0mm on one side;

7. After the slider is pulled out, there must be a stroke switch, and the slider limit device with a compression spring and a stop is preferred, as shown in 3 in picture 1;

8. A wear plate is required for the locking part of the slider, as shown in 4 in picture 1, the slider and the top of the entrance of the locking block make an R angle.

Unique Solutions Mold Profile

Dec 27, 2021USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square...view

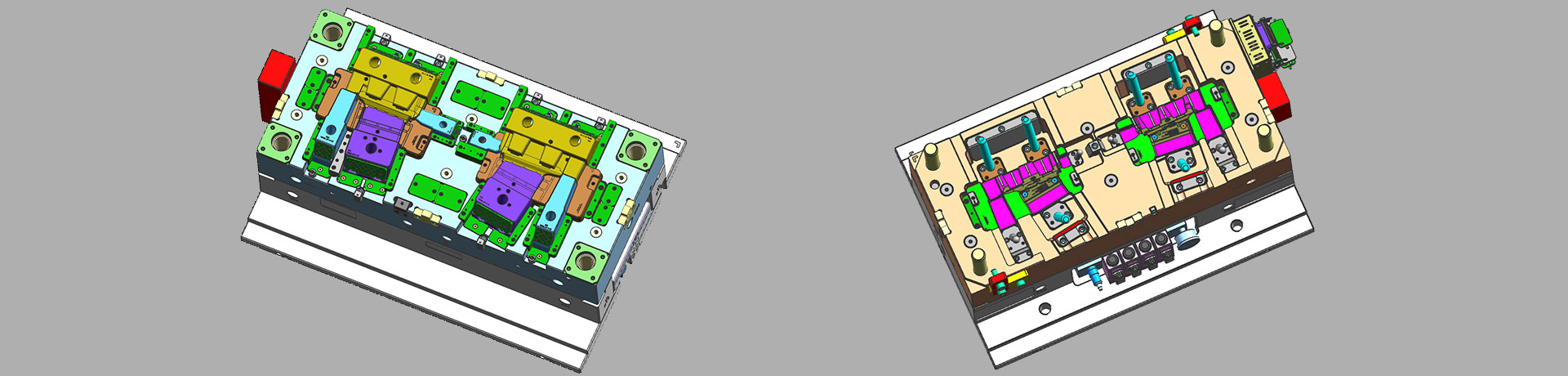

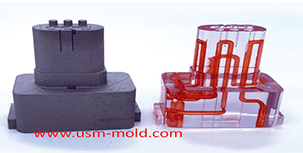

Conformal cooing channel of plastic injection mold

Feb 23, 2022The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product...view

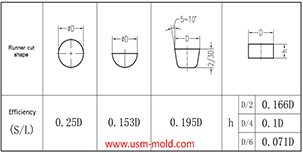

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

Direct gate of plastic injection mold runner system design

Jan 19, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

The air trapping position in cavity and exhaust method

Mar 2, 2022The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...view

English

English русский

русский