Design principles for wall thickness of plastic products

The principles of wall thickness design for plastic parts are as follows:

1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking even, good molding, high dimensional accuracy and high productivity. If the wall thickness can not be even due to some special requirements of plastic parts, the inclined plane should be used to gradually transition between the thick and thin walls. In addition, the ratio of thickness must be strictly controlled as follows: thermosetting plastic: pressing 1:3, extruding 1:5 thermoplastic: injection molding 1: (1.5~2);

2. Under the conditions of meeting the requirements of the structure and use of the plastic parts, use a smaller wall thickness as much as possible, so that we can get: the mold cools quickly, the part weight is light and saving material:

3. The design of the wall thickness of the plastic part should be able to withstand the impact and vibration of the mold ejection device, etc.;

4. There must be sufficient thickness at the connection and fastening place of the plastic part, the place where the insert is buried, and the junction of the plastic melt at the hole (welding mark);

5. When determining the wall thickness, the required strength during storage and handling must be considered;

6. To meet the wall thickness required for melt filling during molding, it is necessary to avoid insufficient filling or thin walls that are easy to burn, but also to avoid melt fracture or thick walls that are easy to produce depressions;

7. Different plastics have different reasonable wall thicknesses due to their different fluidity, see list 1 for details;

8. The fire rating required by the product, different fireproof grades correspond to different product wall thicknesses, if the product wall thickness has been determined, in order to achieve the required fireproof grade, it is often necessary to replace higher grade materials, if there is no suitable material, then it needs to be increased product wall thickness.

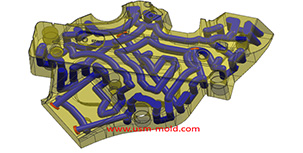

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

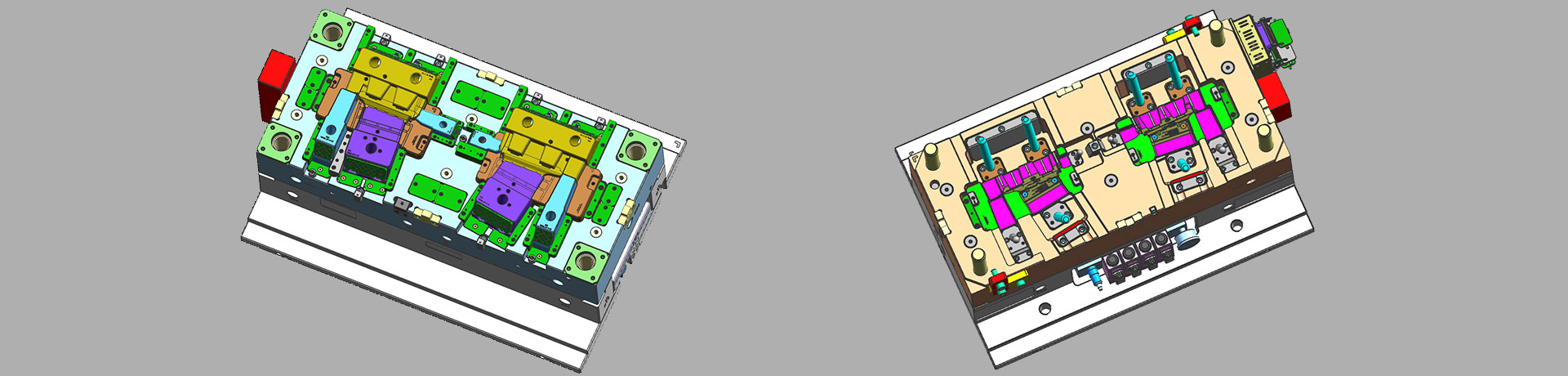

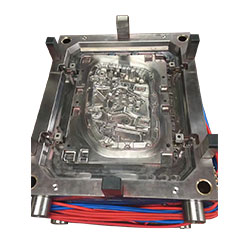

Unique Solutions Mold Profile

Dec 27, 2021USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square...view_20250317091113A018.jpg)

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

Gas-assisted Injection Molding Equipment

Apr 10, 2022The gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection...view

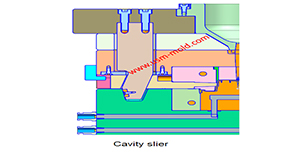

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

English

English русский

русский